Link to the World

MADE IN JAPAN

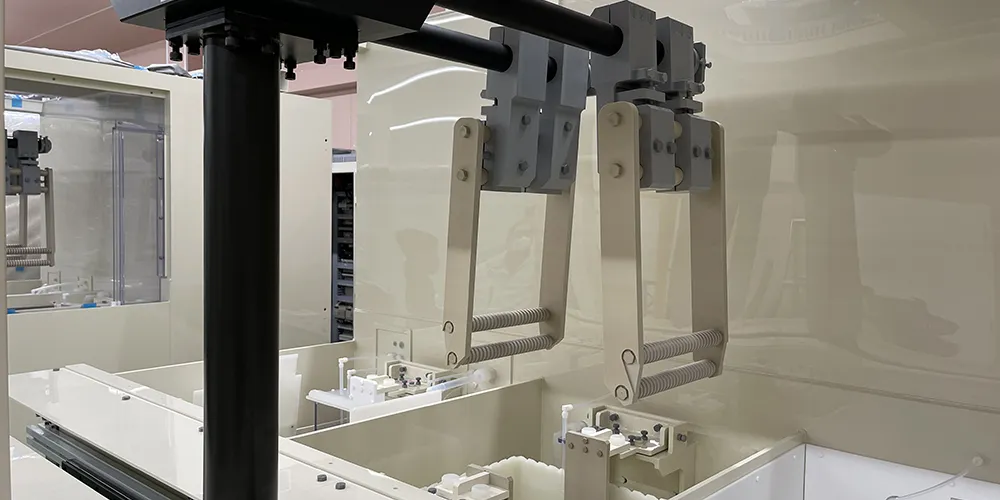

Wafer Cleaning Equipment Series

Semiconductor devices are manufactured by repeatedly applying microfabrication technology to a high-purity single-crystal silicon substrate, known as a "wafer". As a specialist manufacturer of transport systems (in-process wafer transport devices, inter-process wafer transport devices, stocker transport devices) and cleaning devices (peeling cleaning devices, single-type cleaning devices, batch-type cleaning devices) for semiconductor manufacturing equipment, PHT particularly supports the manufacturing processes of 300mm wafers for advanced devices and 200mm wafers for IoT and automotive applications. In order to meet the demands of further miniaturization and high performance required by next-generation semiconductor technologies, we are advancing the development of more precise transport and cleaning technologies, and continue to contribute to the development of the semiconductor industry.

Boasting a world-class share in automatic wafer peeling devices (peeling cleaning machines), PHT utilizes cutting-edge transport robot technology and advanced cleaning equipment technology to design and manufacture indispensable transport systems and wafer cleaning equipment for semiconductor manufacturing. These devices achieve stable operation in semiconductor manufacturing processes that require advanced clean environments, and maintain high reliability even in long-term operation. In fact, some of PHT's devices have been in operation for over 20 years and continue to function properly, demonstrating no increase in metal contamination or particles. PHT will continue to promote technological innovations that support the high functionality and high performance of semiconductors, contributing to the development of the industry.

PHT, with its extensive track record in silicon wafer transport and cleaning technology, leverages its advanced know-how to support the manufacturing processes of next-generation power semiconductor materials such as SiC (silicon carbide) and GaN (gallium nitride). In particular, these new materials require improved power efficiency and high voltage resistance, making advanced transport and cleaning technology indispensable, different from traditional silicon wafers. To meet these needs, PHT provides optimal transport system solutions (robots, transport and transfer devices, EFEM, sorters), and develops and provides cleaning equipment solutions (automatic peeling cleaning devices, precision cleaning devices) that ensure wafer quality and improve yield. As a result, PHT contributes to the improvement of reliability and productivity in the production sites of next-generation semiconductors, and continues to support the development of the industry.

The competitiveness of PHT's semiconductor cleaning equipment is the world's first modularization of each unit. The main purpose of cleaning in the pre-process is to remove contaminants generated in each process, and the main purpose of cleaning in the post-process is to remove particles and metals. A typical cleaning method is a cleaning method called RCA cleaning. Utilizing top-level technology, we produce semiconductor manufacturing equipment and have a track record of delivery to top manufacturers. Can be used in all wet processing processes.

We introduce PHT's global base information. With the advancement of technology, borders no longer separate us. Currently, we are working in collaboration with teams all over the world.

1980

1980

182

182

Japan

6Overseas

5 ¥5.0Billion

¥5.0Billion

52%

52%