Products

Carrier Substrate

Products

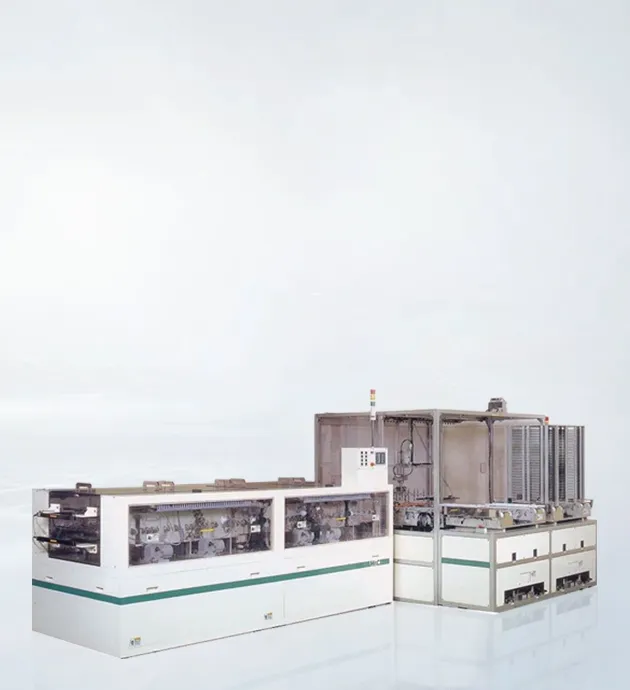

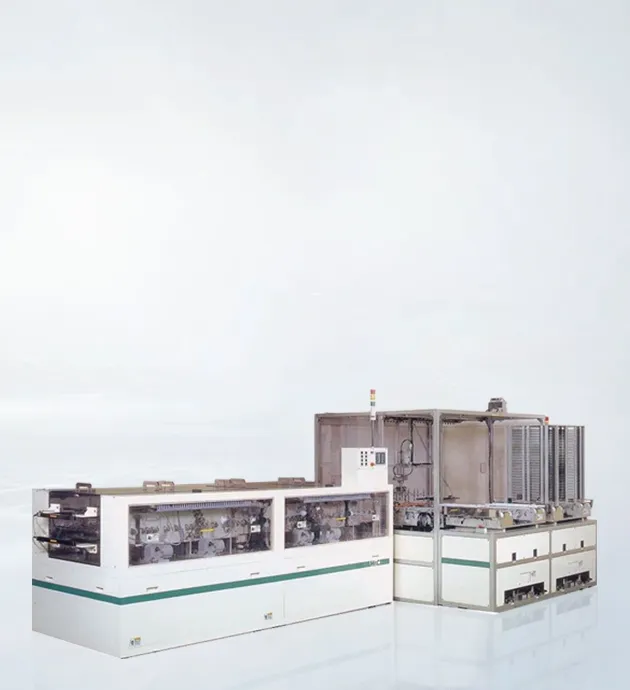

Cutting-edge chiplet packaging technology for next-generation semiconductors is being developed, and glass substrates are expected to be applied as carrier substrates for packaging. Proposals for the transportation and cleaning equipment for these glass carrier substrates are possible.

※ As an option, it is also possible to input sheet by sheet from cassette magazine to robot.

This device is used for cleaning incoming glass substrates. Only pure water (DIW) is used without any chemicals.