Silicon Substrate Processing and Cleaning Equipment

Purpose of Cleaning

-

Pre-process Cleaning:The primary purpose is to remove contaminants that occur during the process.

-

Post-process Cleaning:The main purpose is to remove particles and metals.

The representative cleaning method is called RCA cleaning.

Purpose of RCA Cleaning

The ultimate goal in semiconductor manufacturing is to increase the yield to 100%. Particles and metal contamination greatly affect the yield. Particles cause wire cutting and shorting. Metals are a major cause of noise. These factors significantly manifest in the yield.

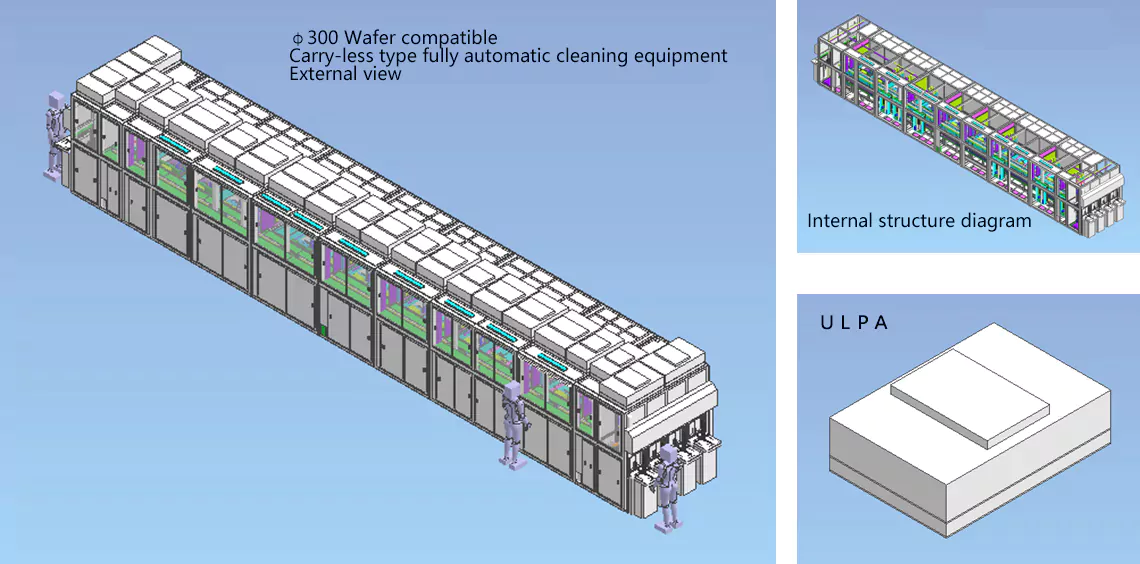

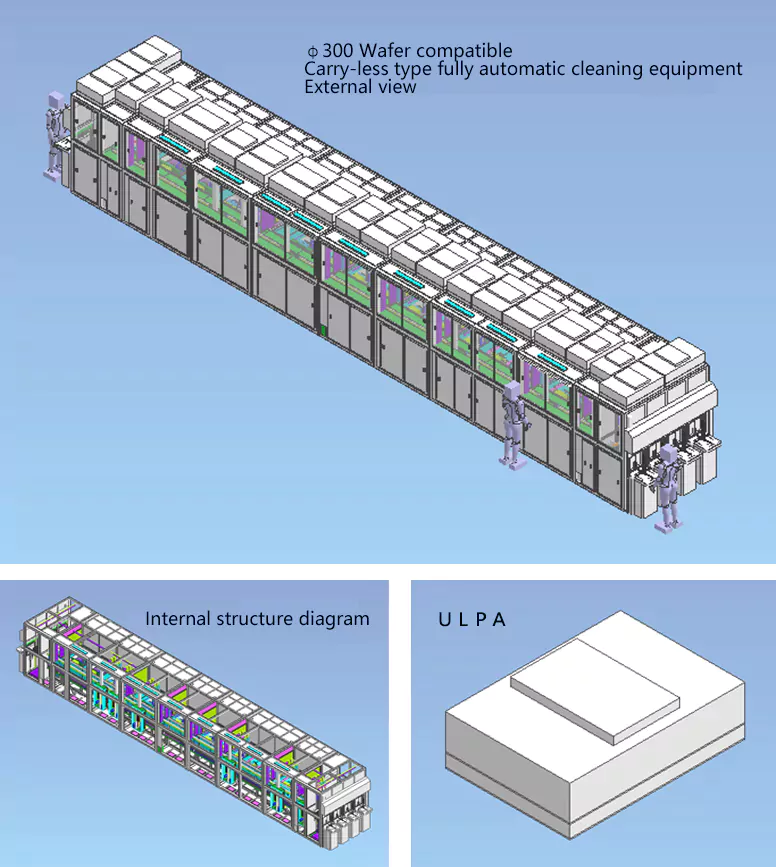

Batch Type Fully Automatic Wafer Cleaning Machine Overall Diagram

What is RCA Cleaning?

-

APM (SC-1) Cleaning:A cleaning method aimed at particle removal. NH4OH + H2O2 + DIW

-

APM (SC-2) Cleaning:A cleaning method aimed at metal removal. HCl + H2O2 + DIW

-

DHF Cleaning:A cleaning method aimed at particle removal / metal removal. HF + DIW

-

SPM Cleaning:A cleaning method aimed at organic matter removal. H2SO4 + H2O2

Silicon Substrate Manufacturing Process

(Red Text Product Lineup)

| Process | Content |

|---|---|

| Monocrystal | CZ method, MCZ method, FZ method |

| Crystal Periphery Grinding Orientation Measurement | Periphery Grinding To understand the crystal orientation, perform olifra or notch processing. |

| Slice |

Diamond Blade: Small Diameter Wafer Wire Saw: Ø8, Ø12 Free Abrasive, Oil-based Abrasive, Water-based Abrasive Fixed Abrasive: Abrasive fixed to the wire (Saw marks tend to appear) |

| Post-Slice Cleaning |

Abrasive removal. Cleaning mainly with alkali + interface In case of Ø12, implemented by a demounter: Wafer cleaning & peeling |

| Beveling | Processing and polishing of the wafer end face are carried out. |

| Lap | Double-sided lapping machine: Used to flatten the wafer. |

| Post-Lap Cleaning Machine | Lapping abrasive removal: Cleaning mainly with alkali + interface. |

| Etching |

Removal of processing distortion occurring during lap machining. Acid etching (diffusion rate determining): Mixed acid solution of HF, HNO3, CH3COOH Alkali etching (reaction rate determining): Concentrated solution of KOH or NaOH |

| Gliding | For Ø12 wafers, gliding is used as a method to increase flatness instead of lapping. There are two methods: double-end grinding and single-end grinding. |

| Alkali Etching | Removal of processing distortion occurring during gliding. |

| Pre-Heat Treatment Cleaning | While RCA cleaning is the basis, it varies depending on the user's line configuration. |

| Heat Treatment |

Gettering BSD: Forms a strained layer on the backside of the wafer by processing to cause gettering. Heat Treatment: Forms a strained layer inside the wafer by heat treatment. There are various methods. |

| Post-Heat Treatment Cleaning | While RCA cleaning is the basis, it varies depending on the user's line configuration. |

| Polishing (Grinding) |

Mirror Polishing: Eliminate the unevenness of the wafer surface to the utmost. Double-sided Polishing: Ø12 is double-sided polished. Single-sided Polishing: Up to Ø8, single-sided polishing is the main method. |

| Post-Polishing Cleaning | Cleaning after polishing: RCA cleaning is the basis, including DHF, SC-1, SC-2, O3 water. |

| Particle Inspection | KLA (Tencor) SP3 |

| Final Cleaning | RCA cleaning is the basic method, including DHF, SC-1, SC-2, O3 water. |